LP Packaging gépek, Packaging Machines, Zsugorfóliázó gépek

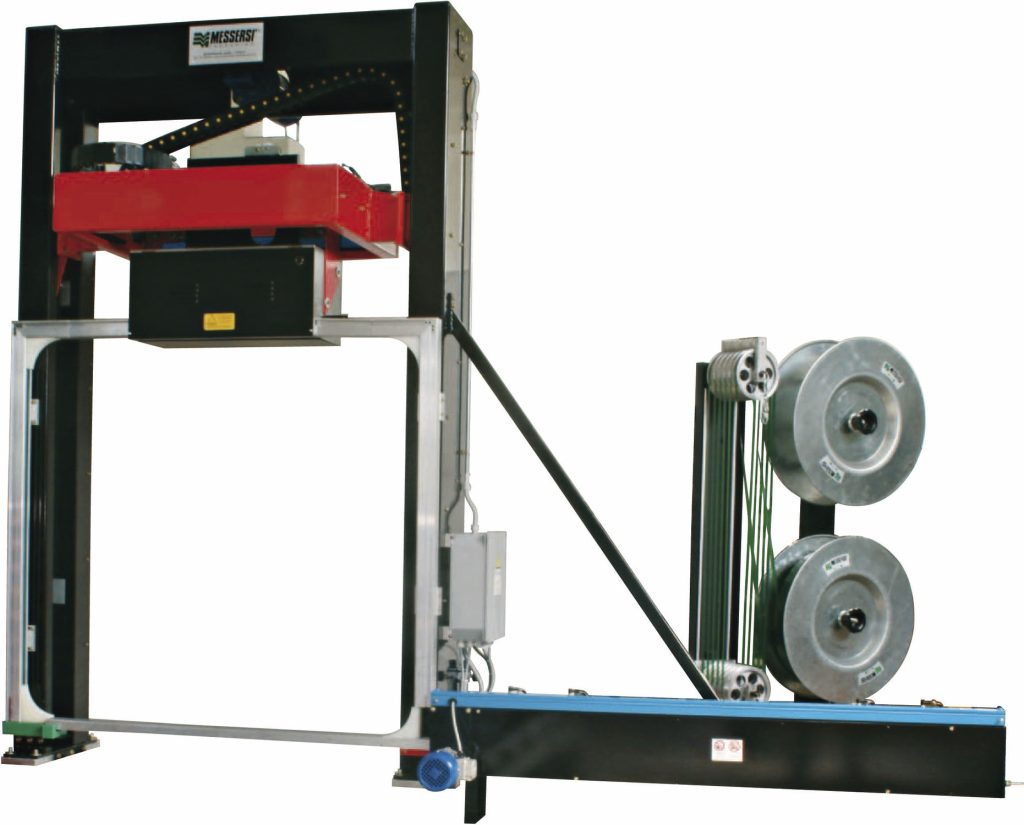

Automatic 90 degree AU shrink wrapping machine

#VALUE!

Machine type: automatic shrink wrapping machine, automatic feeding, 90 degree rotated feeding belt

Packaging, packaging material type: double roll polyethylene film – flat film (LDPE)

Can be fitted into fully automatic lines, where packages are assembled in multiple rows / multiple layers

Full coverage can be achieved by overlapping

It can not only be used as a separate unit, but can also supply a packaging line and a separate shrink tunnel.

| Model | SFE400 AU | SFE 600 AU | SFE800 AU | SFE1100 AU | SFE1500 AU | |

| B | A | |||||

| Max. package height (mm) /400 V 50 Hz voltage/ | 250 | 320 | 350 | 400 | 350 | 600 |

| Welding band width (mm) | 390 | 560 | 760 | 1070 | 1470 | |

| Max. foil roll size (mm) /may vary depending on package characteristics/ | 320 | 500 | 700 | 1000 | 1400 | |

| Production speed (packages/min) | 18 | 18 | 18 | 18 | 18 | |

| Power input (kW) | 8.8 | 8.8 | 17.4 | 22.2 | 29.5 | 34.8 |

The above machine types can be ordered in different versions depending on the product size and the expected growth rate.

Features:

– automatic infeed conveyor with adjustable speed (controlled by inverter)

– product gate separation system

– automatic pack collation (controlled by PLC)

– motorized bottom and top foil unwinder

– sealing unit

– clamping pressure for perfect product stability

– fast cooling sealing

– mesh conveyor shrink tunnel with adjustable speed (controlled by inverter)

– pack cooling fan at the end of the packaging line

Optional:

– electronic version (electronic pack conveyor – servo controlled) for faster packaging speed (25 packs/min)

– duplex version (double pusher and double bottom and top foil unwinder)

– automatic cardboard feeding

– multi-row infeed unit

– forklift

– tamping rollers at the end of the wrapping line

– additional film holder (motorized / non-motorized)