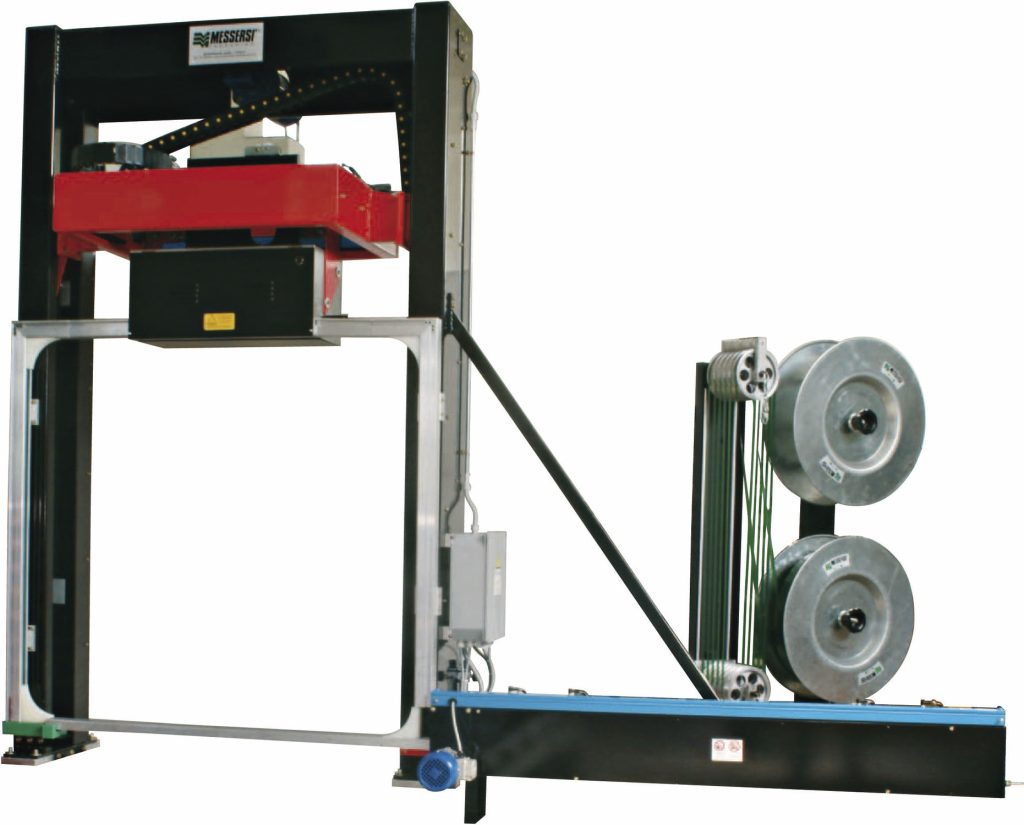

A workstation machine, its task is to wrap the product with special stretch-hood film.

Stretch-hood (Hungarian: stretched film packaging) is one of the most dynamically growing pallet-unifying packaging technologies on the market. The principle is that the stretch hood hose is opened and mechanically stretched in 4 places and pulled onto the pallet unit load. The cohesive force acting on the unit load is significantly higher than in the case of traditional shrink-hood or machine stretch film. Another great advantage of the technology is that there is no need for an expensive and energy-intensive shrink tunnel or heat tunnel, which means at least 30-40% energy savings.

Stretch-hood film allows the packaging to be extremely strong.

Significant cost savings thanks to the thinner film, while providing the product with excellent protection against external influences!

TECHNICAL DATA

- Film used: flexible polyethylene

- Film thickness: 80-140 microns

- Voltage: 400V three-phase – 50 Hz

- Power: 5.5 kW

- Air pressure: 6 bar

- Air consumption / cycle: 50 Nl